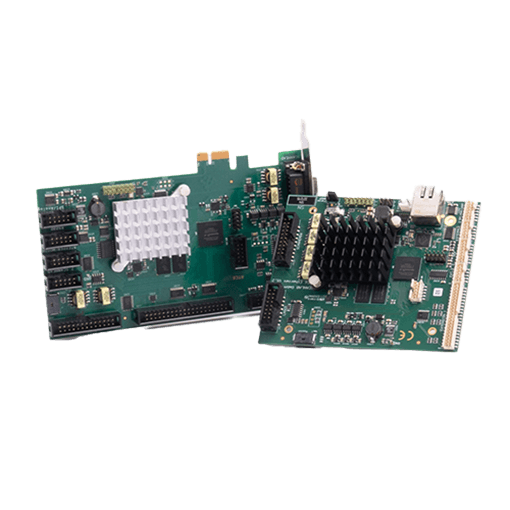

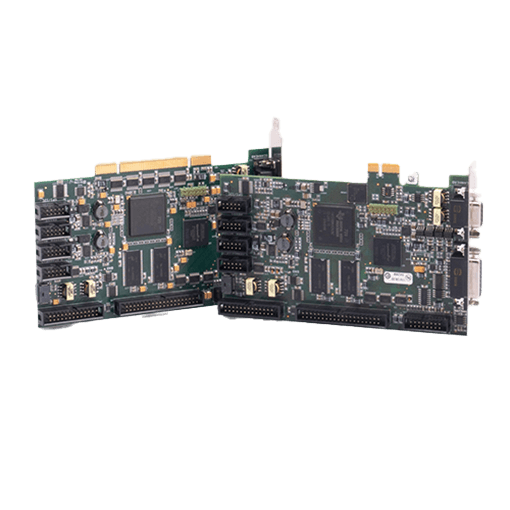

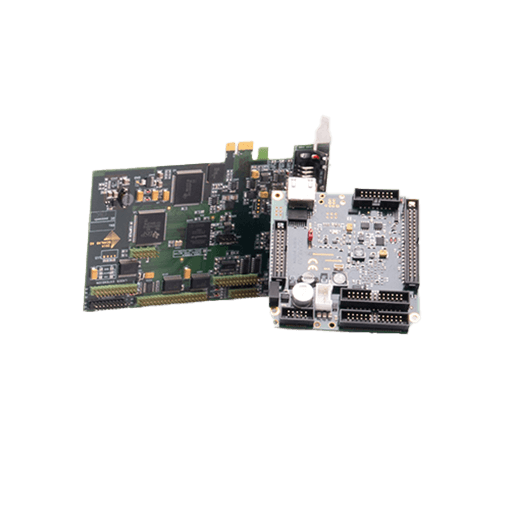

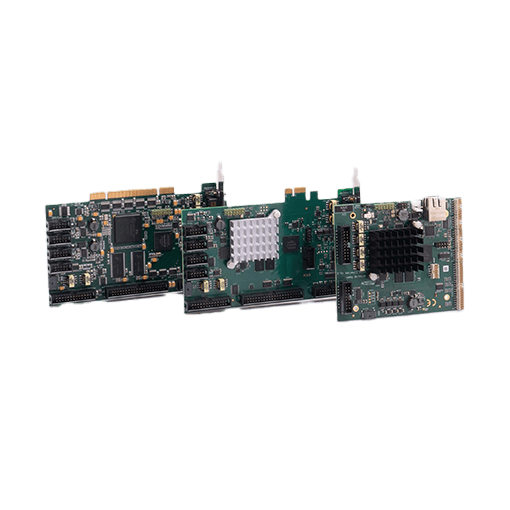

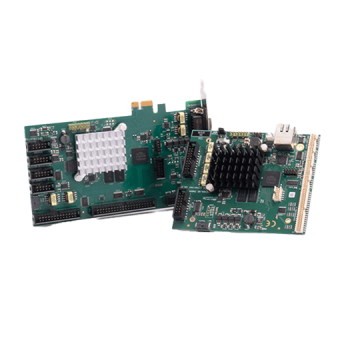

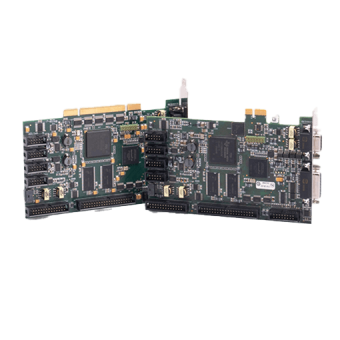

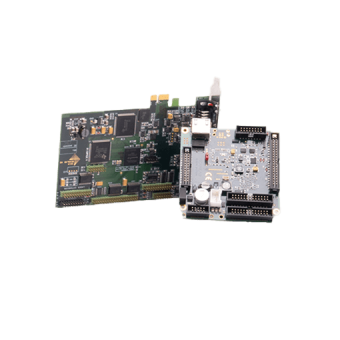

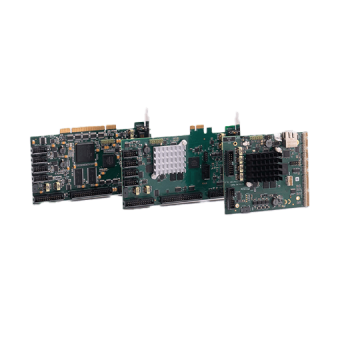

Control boards of the RTC family enable the intelligent and flexible control of scan systems, lasers and peripheral devices in real time. Thanks to the PCI Express or Ethernet interfaces, they can be integrated quickly and flexibly. Software with detailed documentation simplifies the integration into application programs. RTC control boards are supported by many software packages for laser applications.

1) 16 bit at z-axis control

2) optional

3) half measurement data memory when using three or four correction files

4) higher accuracy through extrapolation of the encoder values

5) output pins shared with +5 V or LaserOn signal (configurable by solder jumper)

-

Key Features

- Synchronous control of scan system and laser

- Control modes for all common lasers

- Flexible programming of vector and bitmap processes

- Automatic image field correction

- Support of 3D and processing on the fly applications

-

Overview of RTC6, RTC5 & RTC4

| Product | RTC6 | RTC5 | RTC4 |

| PC interface | PCI Express, Gigabit Ethernet | PCI, PCI Express | PCI Express, Ethernet |

| Standalone operation | yes (Ethernet variant only) | no | no |

| Remote interface | yes (Ethernet variant only) | no | no |

| Data streaming | yes (Ethernet variant only) | no | no |

| Scan head interface

Galvanic isolation

Number / Channels Positioning resolution Connector |

SL2-100 yes 2 / 2 20 bit 9-pin D-SUB |

SL2-100 yes 2 / 2 20 bit1) 9-pin D-SUB |

XY2-100 no 2 / 3 16 bit 25-pin D-SUB |

| Laser connector | 15-pin D-SUB | 15-pin D-SUB | 9-pin D-SUB |

| SCANahead support 2) | yes | no | no |

| Correction file format | ct5 | ct5 | ctb |

| Number of correction files. 2D / 3D | 8 / 8 | 4 / 4 3) | 2 / 1 |

| Number of axes with processing on the fly (POF) | 2 4) | 2 | 2 |

| Value range virtual image field with POF | 29 bit | 24 bit | – |

| List memory | 223 (approx. 8 million) | 220 (approx. 1 million) | approx. 8,000 |

| Recording channels / values | 2 / 224 or 4 / 223 | 2 / 220 or 4 / 219 | 2 / 215 |

| Maximum bitmap pixel frequency | 800 kHz, optional 3,2 MHz | 308 kHz | 50 kHz |

| Analog outputs / Resolution | 2 / 12 bit | 2 / 12 bit | 2 / 10 bit 5) |

| McBSP (OIE support) | yes (yes) | yes (no) | no (no) |

| RS232 interface | yes | yes | yes (Ethernet variant only) |

| Step motor control | yes | yes | yes (PCI Express variant only) |

| Laser synchronization | yes (n x 100 kHz) | yes | no |

| Laser delay resolution | 1/64 μs | 1/2 μs | 1μs |

| Master / Slave | yes | yes | no |

| Sky writing modus | yes | yes | no |

| Date / Time / Fonts | yes | yes | no |

| Speed dependent laser control | yes | limited | no |

| IO ports 8 / 16 bit | yes | yes | yes |

2) optional

3) half measurement data memory when using three or four correction files

4) higher accuracy through extrapolation of the encoder values

5) output pins shared with +5 V or LaserOn signal (configurable by solder jumper)

-

Options

| Product | RTC6 | RTC5 | RTC4 |

| Control of 3-axis scan systems |

¡

|

¡ | ¡ |

| Processing on the fly functionality for processing moving objects | ¡1 | ¡1 | ¡ |

| Simultaneous control of two scan systems | ¡ | ¡ | ¡ |

| Customized software extensions | ¡ | - | - |

| UltraFastPixelMode (UFPM) for frequencies above 800 kHz | ¡ | - | - |

| Spot Distance Control (SDC) | ¡2 | - | - |

| SCANahead | ¡ | - | - |

| laserDESK | ¡ | ¡ | - |

1 up to eight objects between trigger and marking position; 2D fly functions

2 only with SCANahead and pulse-on-demand lasers

2 only with SCANahead and pulse-on-demand lasers

-

Special Features of the RTC6 Control Board

| Highlights of all RTC6 | Additional highlights of the RTC6 Ethernet |

| SCANahead technology Scan systems with SCANahead control operate independently from the scan speed with the maximal possible acceleration. Thanks to the RTC6, this potential for increasing productivity can be optimally exploited |

Data streaming Scan system status data and status of the RTC6 Ethernet control board can be permanently and job-independently transmitted to any application program. |

| Multiplexing The latest generation of scan systems support the transmission of several scan system parameters via the SL2-100 return channel to the RTC6. The data can be used for analysis and monitoring. |

Standalone functionality PC-independent control of scan systems: Predefined laser jobs can be stored in flash memory and started by a system controller. |

| Short Vector Processing Software extension for preprocessing short, collinear marks. This can significantly reduce process time in many cases. Short Vector DLL is an add-on software – contact us to find out more! |

Remote interface Platform-independent remote control of the RTC6 Ethernet control board: Allows easy connection to PLCs, Linux systems or embedded PCs. |

-

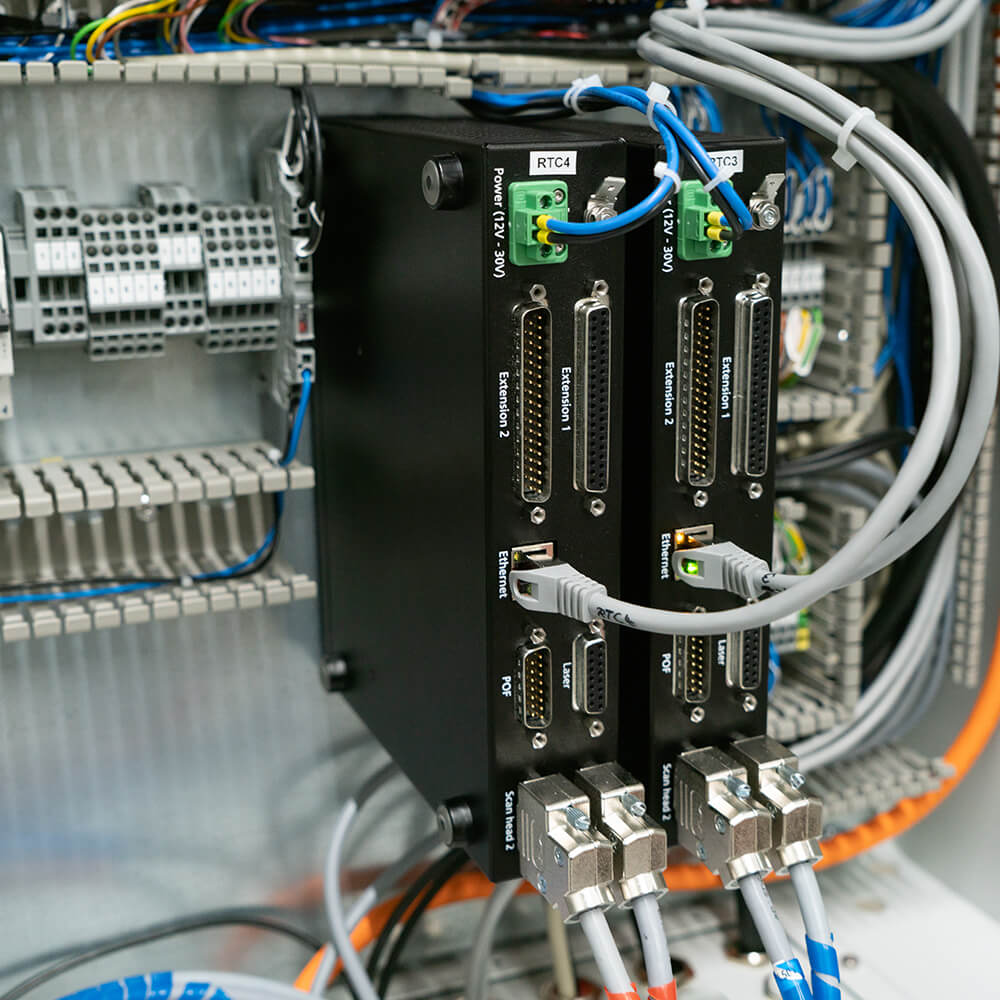

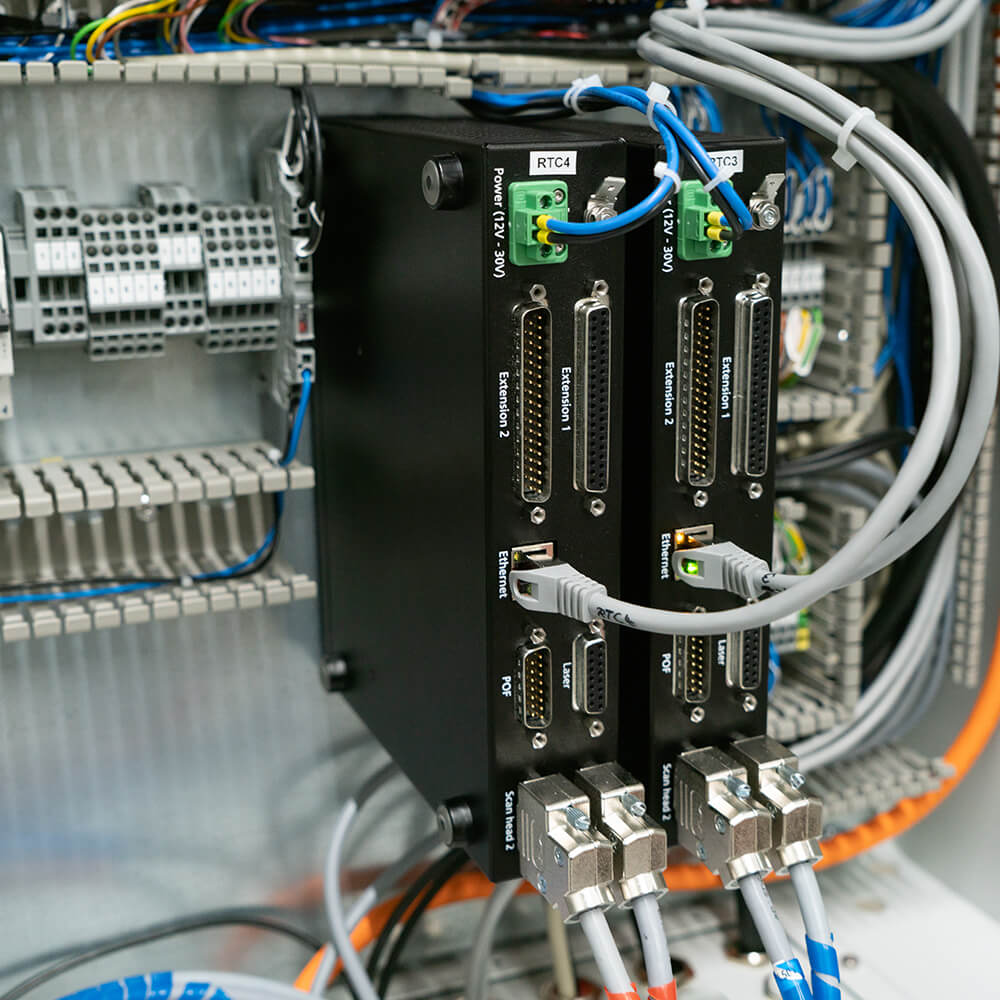

RTC6 EtherBox

The RTC6 Ethernet is also available in a high-quality housing and can be quickly integrated into control cabinets thanks to the top-hat rail bracket.

- Advantages:

- Compact construction in a valuable design

- Simple control cabinet integration via top-hat rail bracket

- Synchronization of multiple RTC6 EtherBox units possible